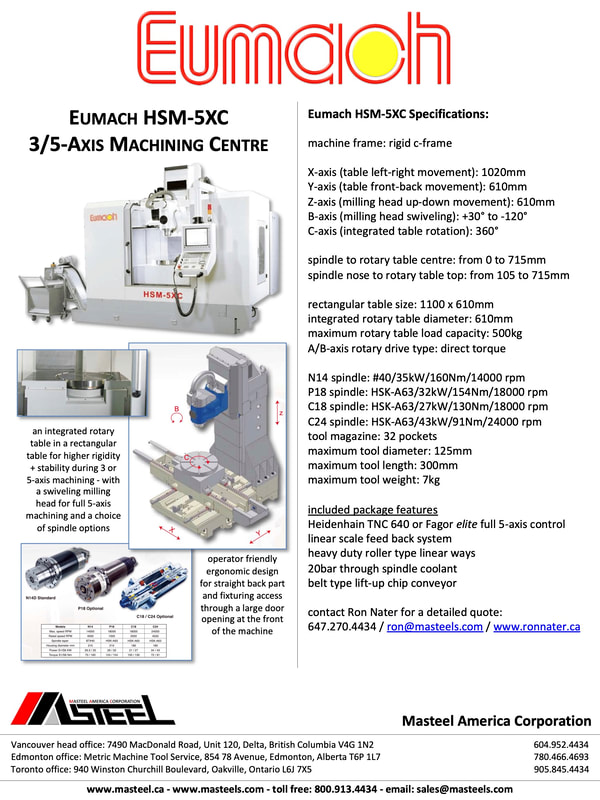

COST-EFFECTIVE SMALL TO MEDIUM PART SIZE 3/5-AXIS MACHINING CENTRES

The Eumach HSM-5XC 3/5-Axis Machining Centre Benefits

The rectangular table with the integrated flush-mounted rotary table surface is highly accessible through a large combined front/top door opening with free access for overhead crane loading. With this ergonomic machine design (as the table travels from the front to the back in the Y-axis) this machine offers very operator friendly straight back part + fixturing access for set-up and checking.

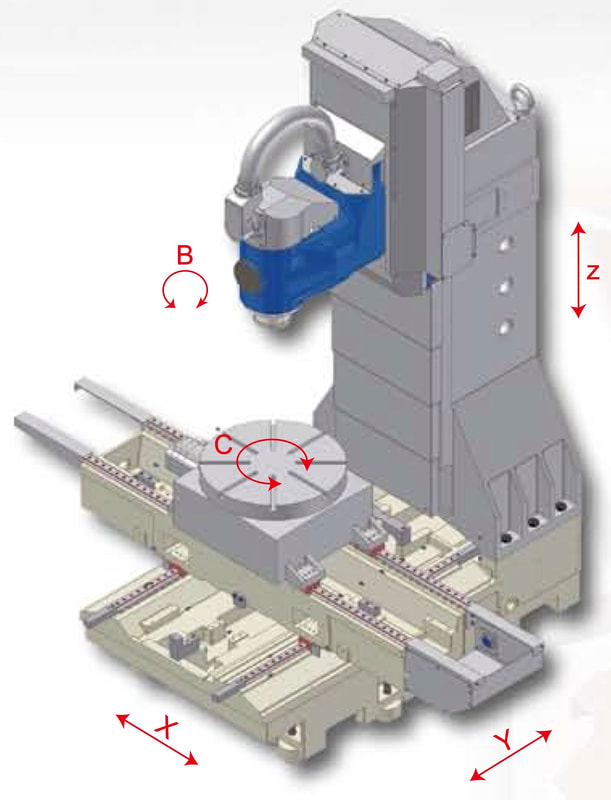

The single axis rotary table integrated in the rectangular table (combined with a single axis swiveling milling head for full 5-axis machining) offers high rigidity + stability during 3/5-axis machining (as there is no simultaneous table tilting/rotating for the 5-axis machining movements eliminating any 2-axis trunnion fixture deflection as associated with a 2-axis trunnion table) and a larger 3-axis machining table support surface:

The rectangular table with the integrated flush-mounted rotary table surface is highly accessible through a large combined front/top door opening with free access for overhead crane loading. With this ergonomic machine design (as the table travels from the front to the back in the Y-axis) this machine offers very operator friendly straight back part + fixturing access for set-up and checking.

The single axis rotary table integrated in the rectangular table (combined with a single axis swiveling milling head for full 5-axis machining) offers high rigidity + stability during 3/5-axis machining (as there is no simultaneous table tilting/rotating for the 5-axis machining movements eliminating any 2-axis trunnion fixture deflection as associated with a 2-axis trunnion table) and a larger 3-axis machining table support surface:

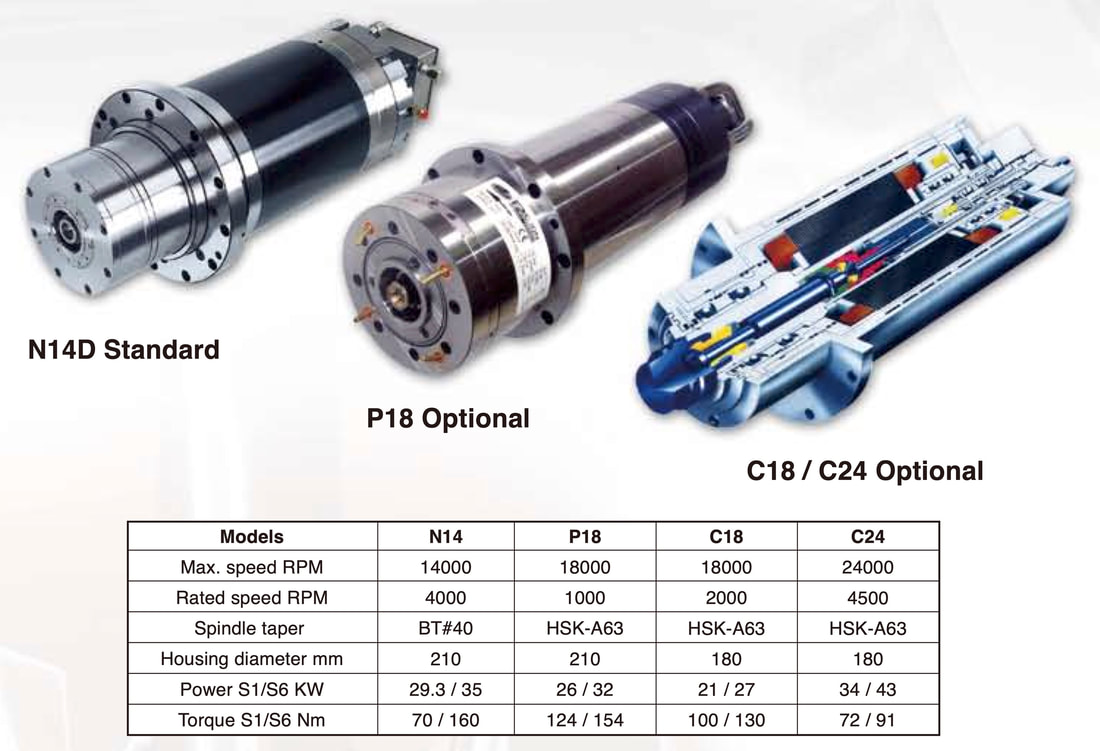

And the machine offers a variety of spindle choices to best-fit specific 3/5-axis machining applications.

The Eumach HSM-5XC Machining Centre Specifications

Rectangular Table

Table length x width = 1100 x 610mm

Rotary Table

Table diameter = 610mm

Maximum load capacity = 500kg

Travel

X-axis table left-right movement = 1020mm

Y-axis table front-back movement = 610mm

Z-axis milling head up-down movement = 610mm

B-axis milling head swiveling = from +30° to -120°

C-axis integrated table rotation = 360°

Distances

Spindle to rotary table centre = from 0 to 715mm

Spindle nose to rotary table top = from 105mm to 715mm

Spindle Choices

- BT or CAT#40 / 35kW / 160Nm / 14000 rpm

- HSK-A63 / 32kW / 154Nm / 18000 rpm

- HSK-A63 / 27kW / 130Nm / 18000 rpm

- HSK-A63 / 43kW / 91Nm / 24000 rpm

Rapid Feed Rates

Rapid X/Y/Z axis = 30m/30m/24m per minute

Automatic Tool Changer

Number of tool pockets = 32

Maximum tool diameter = 125mm

Maximum tool length = 300mm

Maximum tool weight = 7kg

Table length x width = 1100 x 610mm

Rotary Table

Table diameter = 610mm

Maximum load capacity = 500kg

Travel

X-axis table left-right movement = 1020mm

Y-axis table front-back movement = 610mm

Z-axis milling head up-down movement = 610mm

B-axis milling head swiveling = from +30° to -120°

C-axis integrated table rotation = 360°

Distances

Spindle to rotary table centre = from 0 to 715mm

Spindle nose to rotary table top = from 105mm to 715mm

Spindle Choices

- BT or CAT#40 / 35kW / 160Nm / 14000 rpm

- HSK-A63 / 32kW / 154Nm / 18000 rpm

- HSK-A63 / 27kW / 130Nm / 18000 rpm

- HSK-A63 / 43kW / 91Nm / 24000 rpm

Rapid Feed Rates

Rapid X/Y/Z axis = 30m/30m/24m per minute

Automatic Tool Changer

Number of tool pockets = 32

Maximum tool diameter = 125mm

Maximum tool length = 300mm

Maximum tool weight = 7kg

the Eumach HSM-5X brochure

the Eumach HSM-5XC 3/5-axis machining centre flyer