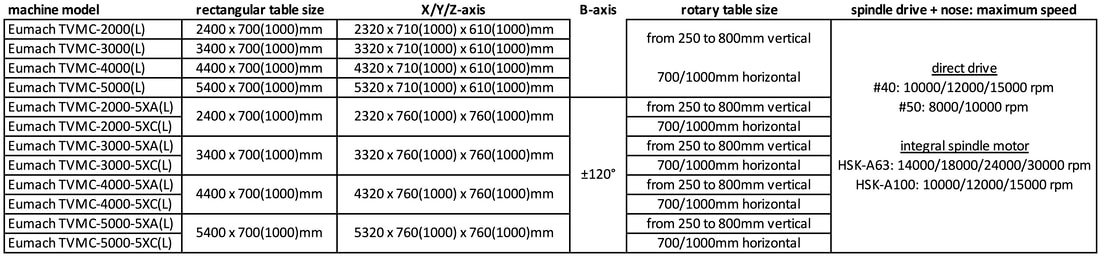

Masteel offers the successful Eumach TVMC fixed table traveling column vertical 3/4/5-axis machining centres (in production for many years now) with the following beneficial features:

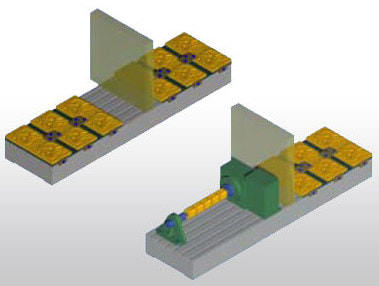

- the side-by-side dual work zones reduce or eliminate non-cutting work piece set-up / load / unload time (depending on the work piece machining time) compared with a single table 3 to 5-axis machining centre (with an average spindle uptime of 30%) or pallet change equipped 3 to 5-axis machining centre - as next work piece set-up is during machining time of the other work piece and there is no pallet change time

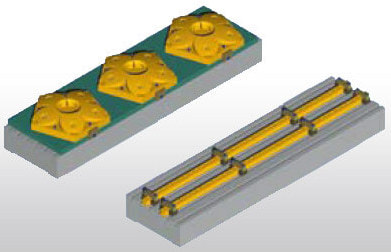

- the fixed table / traveling column construction offers higher rigidity and precision accuracy (due to the elimination of table overhang) compared with a table traveling design

- the fixed table offers easier chip disposal compared with a table traveling machine

- the fixed table allows easy installation and operation of robot part loading and unloading automation and part fixture hydraulics

- swivelling milling head / non-moving rotary table 2-axis combination on a linear 3-axis machining centre for extra work fixture rigidity and stability during 5-axis machining

- up to 30° negative undercutting capability on both sides of the swivelling milling head

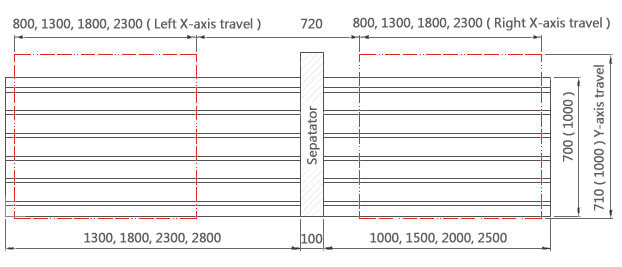

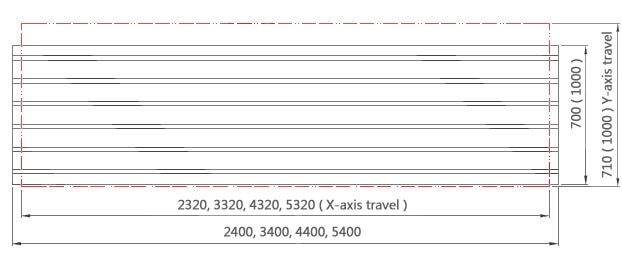

- the centre partition can be removed to obtain an extended single work zone over the full table length

- a variety of spindles to best-fit specific machining applications (from CAT#50 8000 rpm high power to HSK-A63 30000 rpm high speed)

- a variety of tool magazines from 24 to 60 stations

- two work zones to increase spindle uptime -

- one work zone for longer or multiple parts -

the machine brochure

the control brochures

Note that the Fusion 360 CAD / CAM software works on Windows and Mac platforms. So this has become a popular CAM system for turning + machining centre owners / operators using a popular Mac computer (as i do to make my notes).