To get to the point . . .

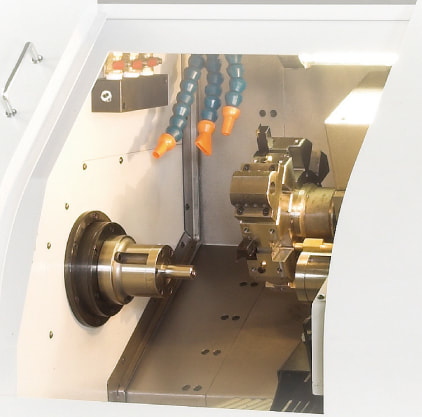

The Po Ly Gim MINI-88 is one of the most cost-effective super compact turning centres for small parts offering the following beneficial features:

- up to 26mm bar capacity @ 5000 rpm on the MINI-88*

- up to 21mm bar capacity @ 8000 rpm on the MINI-88-20

- up to 60mm turning diameter x 120mm turning length on the MINI-88

- up to 21mm turning diameter x 100mm turning length on the MINI-88-20

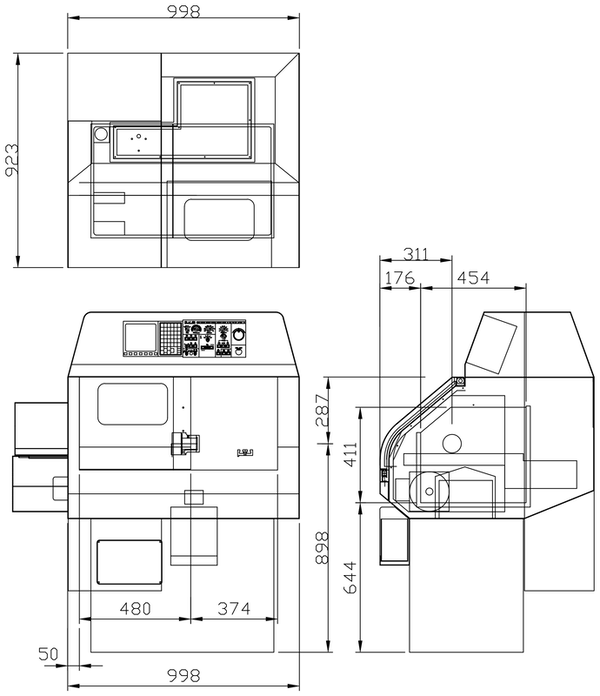

- minimum shop space requirements:

- up to 21mm bar capacity @ 8000 rpm on the MINI-88-20

- up to 60mm turning diameter x 120mm turning length on the MINI-88

- up to 21mm turning diameter x 100mm turning length on the MINI-88-20

- minimum shop space requirements:

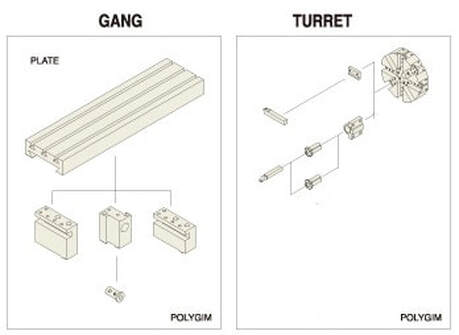

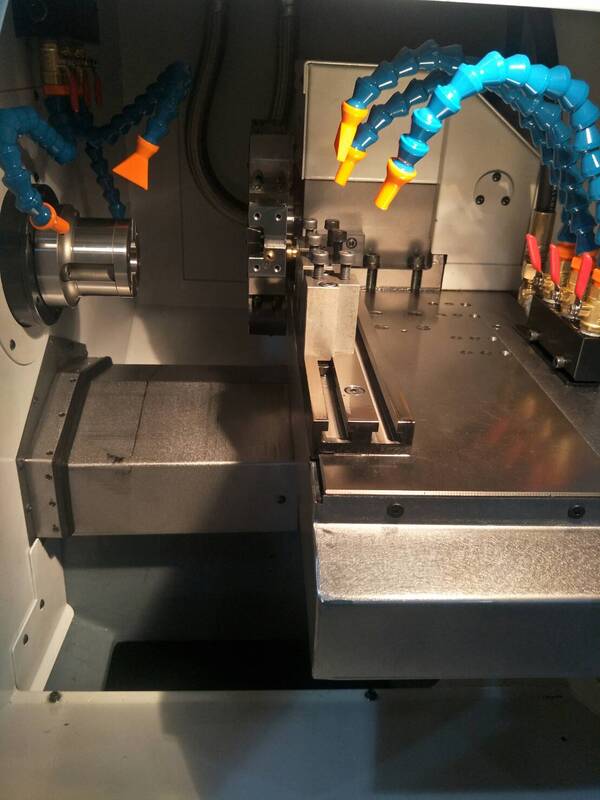

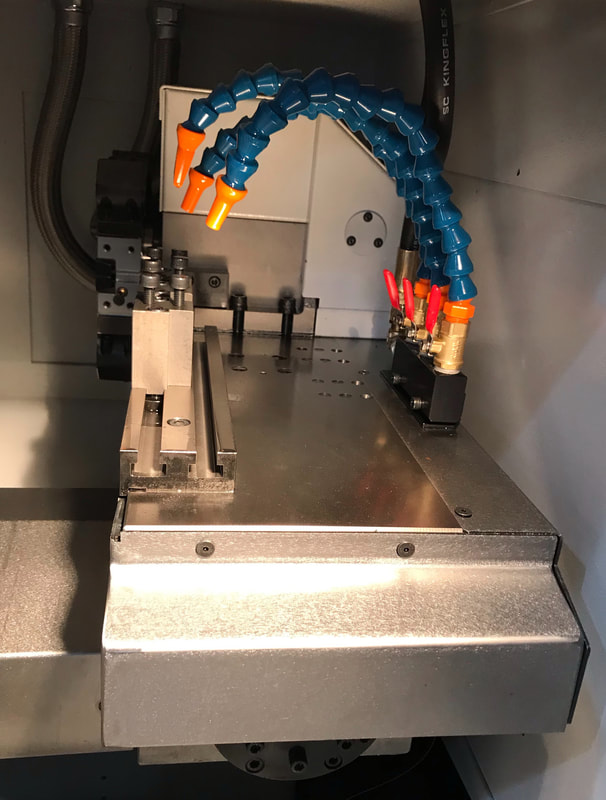

- up to 8 gang plate mounted tool stations (on the MINI-88-20) to eliminate turret indexing time:

- optional 8-station servo turret (on the MINI-88) with up to 11 tool stations on the servo turret / gang plate combination for increased tooling versatility:

- with optional built-in automatic part loading/unloading systems for lower cost high production:

model A step one - material loading

model A step two - material loaded onto spindle

model B step one - material loading

model B step two - material loaded onto spindle

model B step three - material clamped by chuck for cutting

model B step four - work piece unloaded by parts catcher

- with optional part loader/unloader robot:

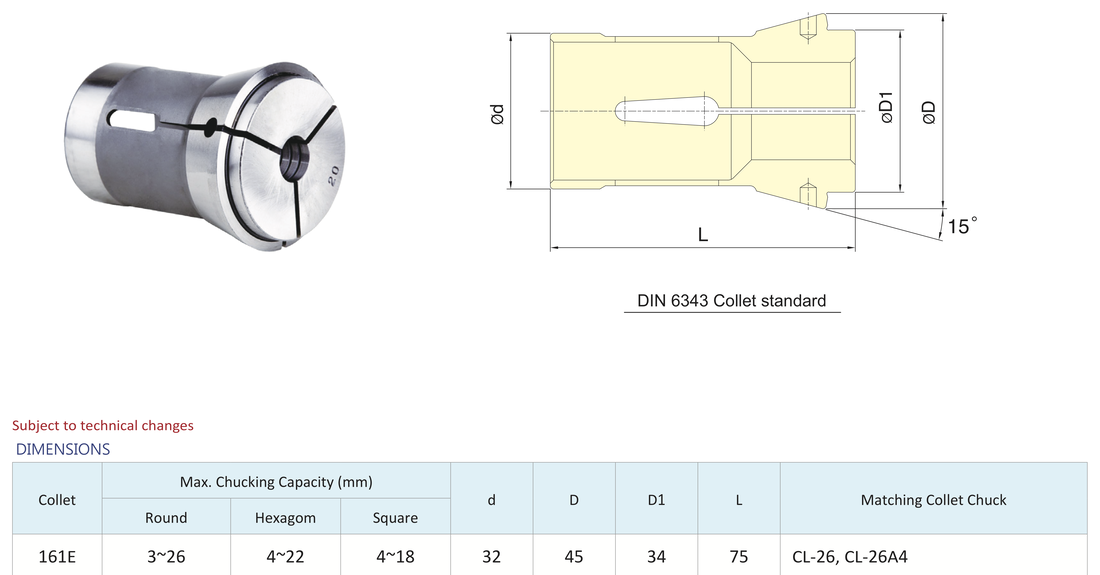

*using a collet chuck with 161E collets to DIN 6343 standards:

- the MINI-88Y with additional C + Y-axis milling/drilling capability:

- offering 18 tool stations (6 o.d tool stations, 4 i.d. tool stations, 4 cross driven tool stations, 4 face driven tool stations):

- and the MINI-88-25 double spindle turning centre:

- up to 80mm turning diameter x 220mm turning length

- with 8-station servo turret and left and right turning spindles:

- with 8-station servo turret and left and right turning spindles:

The Po Ly Gim MINI-88 turning centre brochures:

The Mitsubishi M80 + Fanuc 0i-TF Plus control brochures: